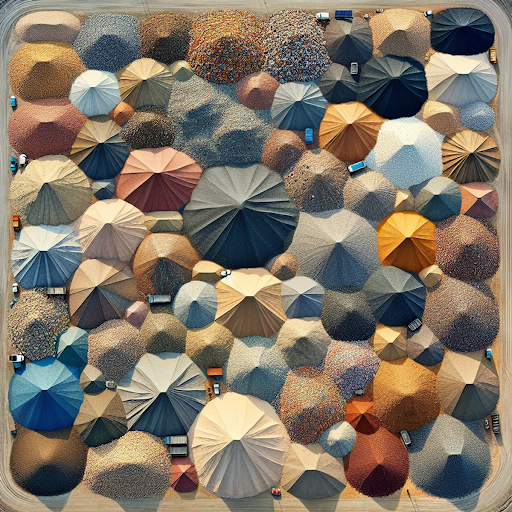

Aggregates are essential components in the construction industry, playing a crucial role in the creation of materials like concrete and asphalt. They are vital for ensuring the strength, durability, and overall effectiveness of these materials.

Importance of Aggregates in Construction

Aggregates are crucial in construction for several reasons:

- Strength: They add bulk and strength to concrete and asphalt.

- Durability: Carefully chosen aggregates can improve the lifespan of structures.

- Cost-effectiveness: Aggregates act as affordable fillers, reducing the overall expense of construction materials.

Overview of Different Types of Aggregates

Different types of aggregates are used in construction, each with its own specific purposes based on its unique properties. Here are some common ones:

- Type 1 Aggregates (Granite): Used mainly for decorative purposes and composed primarily of feldspar, quartz, and mica crystals.

- Limestone Aggregates: Widely utilized in road construction and reinforced concrete due to their durability.

- Gravel/Ballast Aggregates: Cost-effective and safe option with low radioactive content.

- Secondary Aggregates: Made from recycled construction waste, providing a sustainable and cost-effective alternative to primary aggregates.

- Sand Aggregates: Extensively used for adding bulk and strength in both asphalt and concrete.

These various types serve different needs within the industry, ensuring that projects can achieve desired outcomes effectively.

To learn more about how different aggregates impact construction projects, you can refer to C3S Inc.’s Projects Archive or explore detailed case studies like Aggregate Matters which provide valuable insights into the performance of different aggregates across various applications.

Understanding these types helps in selecting the right aggregate for specific applications, optimizing both performance and cost-efficiency in construction projects.

Aggregates in Construction

Aggregates are a fundamental component in the construction industry, playing a critical role in both concrete and asphalt applications. Their primary function is to provide bulk, strength, and stability to construction materials.

Concrete Aggregates

Concrete is composed of approximately 80% aggregates by volume. The inclusion of aggregates in concrete helps to:

- Enhance volume stability.

- Increase the wear resistance.

- Improve the overall durability.

The choice of aggregates impacts the concrete’s properties such as workability, strength, and durability. For instance, high-quality granite aggregates contribute to stronger and more durable concrete structures. To ensure the desired performance of your concrete structure, you can opt for appropriate concrete testing methods that are based on its suitability and intended use.

Asphalt Aggregates

In asphalt production, aggregates make up about 95% of the mixture by weight. These aggregates serve several purposes:

- Provide structural strength to the pavement.

- Ensure load distribution.

- Enhance resistance to weathering and traffic wear.

Aggregates used in asphalt must meet stringent quality requirements to ensure long-lasting road performance. Limestone aggregates are often preferred for their durability and ability to bond well with asphalt binder.

Aggregates not only form the bulk of construction materials but also significantly influence their performance characteristics. Understanding the role of different types of aggregates can help in selecting the right material for specific applications. For example, when dealing with issues like asbestos-cement pipe failure, it becomes crucial to conduct a comprehensive analysis including factors like depth of carbonation through tests such as phenolphthalein test and petrographic analysis.”.

1. Type 1 Aggregates

Type 1 aggregates, commonly known as granite aggregates, are essential in various construction projects due to their durability and aesthetic appeal.

Composition of Granite Aggregates

Granite aggregates are made up of:

- Feldspar: A group of minerals that form about 41% of the Earth’s continental crust by weight.

- Quartz: Known for being hard and resistant to weathering, making it important in concrete.

- Mica Crystals: Add unique reflective properties and enhance the visual appeal of the aggregate.

Uses of Type 1 Aggregates

Granite aggregates have a wide range of decorative uses. They are perfect for:

- Landscaping: Improving the look of gardens and public spaces.

- Driveways and Pathways: Creating visually appealing and long-lasting surfaces.

- Architectural Features: Adding texture and beauty to facades, columns, and other structural elements.

By using granite aggregates, construction projects not only have strong foundations but also look more attractive.

2. Limestone Aggregates

Limestone aggregates are essential in the construction industry because they are versatile and reliable. They are made up mostly of calcium carbonate and are sourced from sedimentary rock formations. These aggregates are abundant in nature, making them a cost-effective choice for various construction purposes.

Importance in Road Construction

Limestone aggregates play a crucial role in road construction projects. They have strong physical properties that ensure the durability and long lifespan of road surfaces. The crushed limestone has angular shapes that fit together well, providing excellent stability and strength to the pavement structure. This results in roads that can withstand heavy traffic loads and harsh weather conditions.

Role in Reinforced Concrete

In reinforced concrete, limestone aggregates are vital for maintaining structural integrity and strength. Limestone has a high compressive strength, making it perfect for creating concrete that can support heavy loads. Its low thermal expansion coefficient also helps prevent cracks caused by temperature changes, ensuring that concrete structures remain sturdy over time.

Key Benefits:

- Durability: Enhances the lifespan of roads and concrete structures.

- Cost-effectiveness: Naturally abundant and economically viable.

- Strength: Provides superior load-bearing capacity.

Limestone aggregates are not just ordinary construction materials; they are essential elements that improve the performance and sustainability of construction projects.

3. Gravel/Ballast Aggregates

Gravel and ballast aggregates are widely used in construction due to their cost-effectiveness and versatility. These aggregates consist of naturally occurring materials such as pebbles, cobbles, and larger stones, making them a popular choice for various applications.

Cost-Effectiveness

One of the primary advantages of gravel/ballast aggregates is their affordability. As a naturally abundant material, gravel is often cheaper than other types of aggregates. This cost savings can be significant when used in large-scale projects such as road construction, railway ballast, and drainage systems. The economic benefits make gravel an attractive option for budget-conscious projects without compromising on quality.

Low Radioactive Content for Safety

Safety is a critical consideration in construction materials, and gravel/ballast aggregates offer an added advantage due to their low radioactive content. Unlike some other natural materials that may contain trace amounts of radioactive elements, gravel typically exhibits minimal radioactivity. This characteristic ensures that structures built with gravel aggregates meet safety standards and reduce potential health risks associated with prolonged exposure to radiation.

In summary:

- Gravel/Ballast Aggregates: Naturally occurring materials including pebbles and cobbles

- Cost-Effectiveness: More affordable than other aggregates, ideal for large-scale projects

- Low Radioactive Content: Ensures safety by meeting health standards

Selecting gravel/ballast aggregates can provide both economic and safety benefits, making them a practical choice for various construction needs.

4. Secondary Aggregates

Secondary aggregates are derived from the recycling of construction waste, making them an eco-friendly option in the building industry. These materials typically include crushed concrete, bricks, tiles, and other demolition debris that would otherwise be discarded in landfills.

Utilization of Secondary Aggregates

- Recycling Construction Waste: The utilization of secondary aggregates addresses both environmental concerns and resource scarcity by repurposing construction debris. This practice reduces the demand for raw materials, conserves natural resources, and minimizes the carbon footprint associated with new aggregate production.

- Applications: Secondary aggregates are often used in road construction, as fill material, and in certain types of concrete applications where high strength is not a primary requirement. They provide a practical solution for non-structural applications while promoting sustainability.

Cost-Effectiveness Compared to Primary Aggregates

- Economic Efficiency: One of the most appealing aspects of secondary aggregates is their cost-effectiveness. Since these materials are sourced from recycled waste, they tend to be significantly cheaper than primary aggregates like granite or limestone. This can lead to substantial savings on large-scale construction projects.

- Resource Optimization: Utilizing secondary aggregates optimizes material usage by diverting waste from landfills and reducing the need for virgin aggregate extraction. This dual benefit makes secondary aggregates an economically viable and environmentally responsible choice.

By incorporating secondary aggregates into construction projects, builders can achieve both economic and environmental advantages without compromising on quality.

5. Sand Aggregates

Sand aggregates are crucial in the construction industry as they provide essential materials for various applications. Among the most commonly used types of aggregates, sand is particularly important in both concrete and asphalt production.

Bulk Usage in Construction

- Concrete Production: Sand aggregates make up a significant part of the mixture used to create concrete. Their small particles help fill the gaps between larger aggregate pieces, making the overall mixture denser and more stable.

- Asphalt Production: In asphalt, sand aggregates contribute to the smoothness and durability of the final product. Their fine texture ensures an even spread within the asphalt, which is critical for road surfaces.

Importance for Strength

Including sand aggregates is crucial in ensuring the strength and durability of both concrete and asphalt structures.

- Concrete Strength: The small particles in sand improve the workability of concrete mixes, making them easier to pour and shape. This results in fewer empty spaces and cracks once the concrete hardens, ultimately increasing its structural integrity.

- Asphalt Durability: Sand adds essential compressive strength to asphalt, allowing it to withstand heavy loads and constant traffic. This makes it an ideal choice for building highways and other high-pressure infrastructure.

Using high-quality sand aggregates guarantees optimal performance of both concrete and asphalt structures in various conditions, underscoring their significance in modern construction projects.

Conclusion

Choosing the right aggregate is crucial for the success and durability of any construction project. Each type of aggregate, from granite to secondary aggregates, plays a specific role in enhancing the strength, stability, and aesthetic appeal of structures. By understanding the unique properties and applications of diverse aggregates, construction professionals can ensure optimal performance and cost-efficiency.

FAQs (Frequently Asked Questions)

How are type 1 aggregates composed?

Type 1 aggregates are primarily composed of granite, which consists of feldspar, quartz, and mica crystals. This composition gives them unique properties that make them suitable for various decorative purposes.

Why are limestone aggregates important in road construction and reinforced concrete?

Limestone aggregates are vital in road construction and reinforced concrete due to their strength, durability, and ability to provide a solid foundation. They help enhance the overall quality and longevity of these structures.

What are the advantages of using gravel/ballast aggregates?

Gravel/ballast aggregates offer cost-effectiveness and low radioactive content, making them a preferred choice for construction projects. Their affordability and safety features make them an attractive option for various applications.

How do secondary aggregates contribute to sustainable construction practices?

Secondary aggregates derived from construction waste promote sustainability by reducing the need for primary aggregates. They offer a cost-effective alternative while minimizing environmental impact through recycling and repurposing materials.

Why are sand aggregates important for asphalt and concrete strength?

Sand aggregates play a critical role in providing strength to asphalt and concrete mixtures. Their bulk usage in construction contributes to the structural integrity and overall performance of these materials.

Recent Comments