Asbestos-Cement Pipe Failure Analysis

- Date: 05/12/2017

- Project Type: Maintenance Phase

Asbestos-Cement Pipe Failure Analysis

About this Project

Asbestos-cement pipe was used extensively in the mid-1900s in potable water distribution systems, particularly in the western United States. The Chrysotile Institute estimates asbestos-cement pipe lifespan at 70 years, but actual service life depends largely on pipe condition and working environment. Because thousands of miles of asbestos-cement pipe installed in distribution systems in the U.S. is nearing the end of its useful service life, asbestos-cement pipe condition assessment and strategic replacement planning will need to be done in the coming decade.

Over time, asbestos-cement pipe undergoes gradual degradation in the form of corrosion (i.e., internal calcium leaching due to conveyed water and/or external leaching due to groundwater). Such leaching leads to reduction in effective cross-section, which results in pipe softening and loss of mechanical strength. Accordingly, as the water distribution system ages, the number of asbestos-cement pipe failures increases with time. In light of these risks, an asbestos-cement pipe condition assessment is essential to determine the remaining useful service life and develop a suitable, proactive replacement plan for the distribution system.

In this case, three pieces of a section of an asbestos-cement pipe were presented for evaluation to determine the pipe’s condition and perform a pipe failure analysis. The longest of the three which was in the worst shape was used in the evaluation and pipe failure analysis.

Note – This featured project report is an abbreviated version of the actual report prepared for the client.

Samples

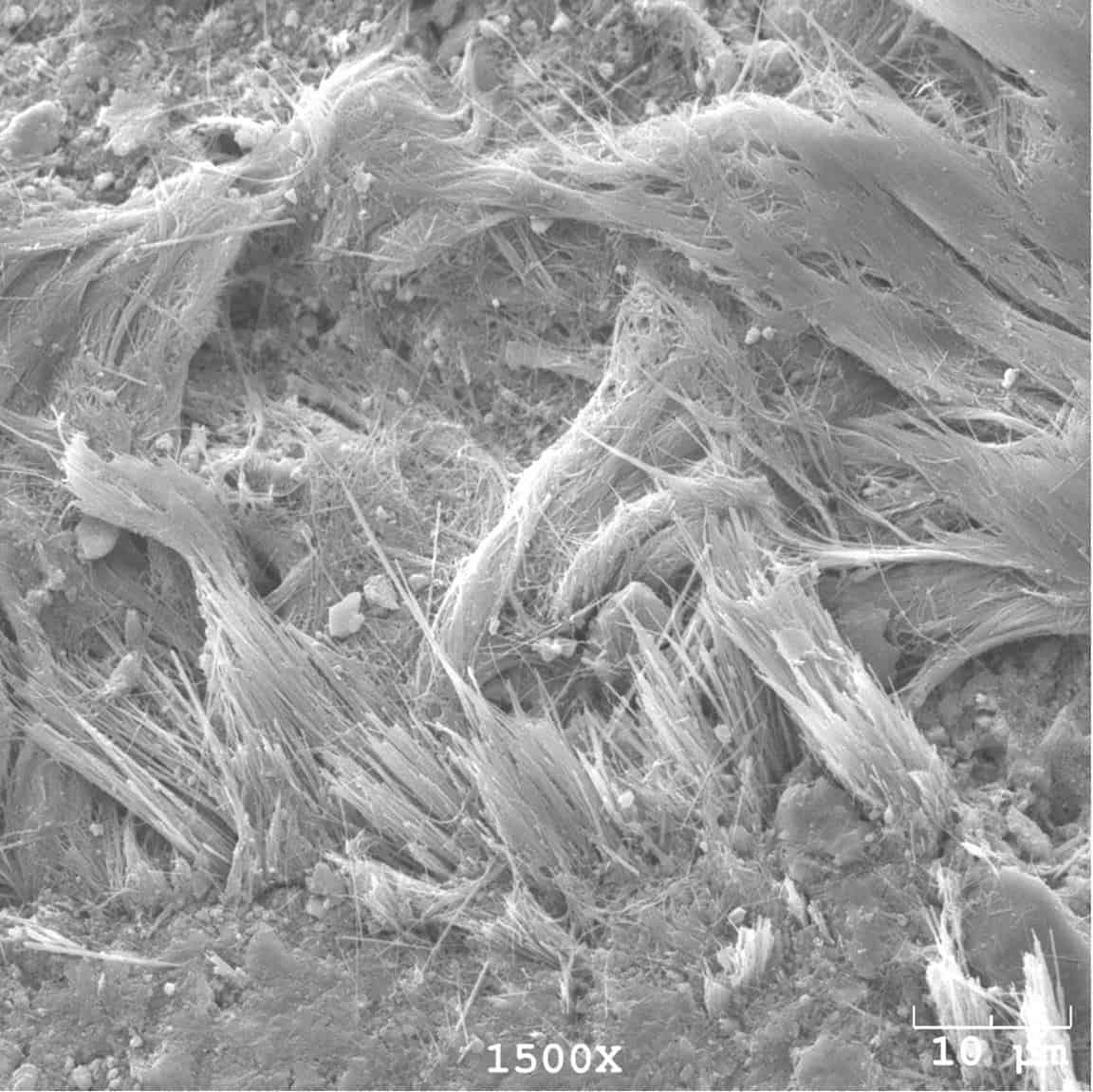

The samples were to be evaluated to determine depth of carbonation as per the phenolphthalein test, petrographic analysis according to ASTM C856 and SEM/EDX as per ASTM C1723-10.

Test

Petrographic Examination of Hardened Concrete

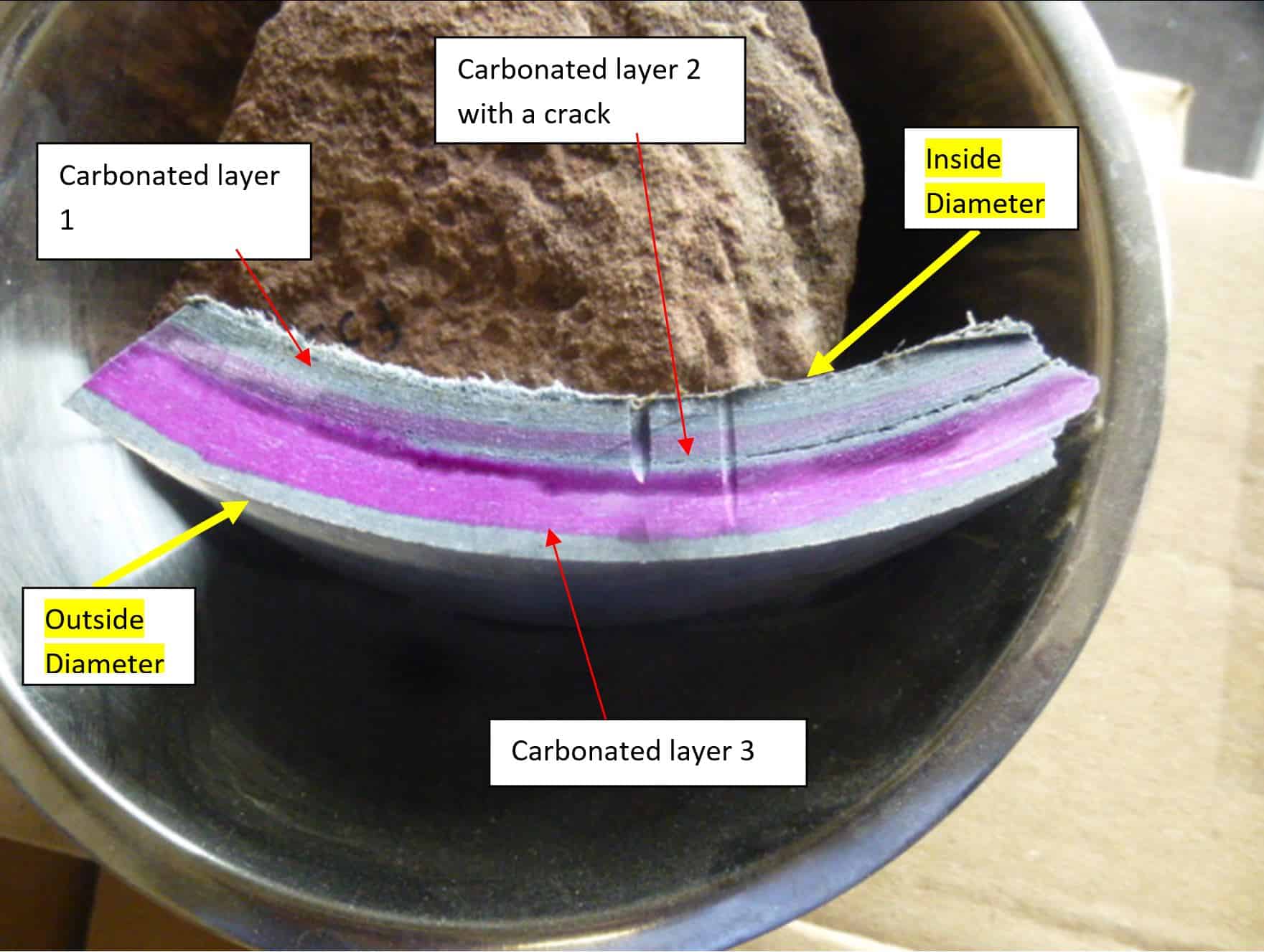

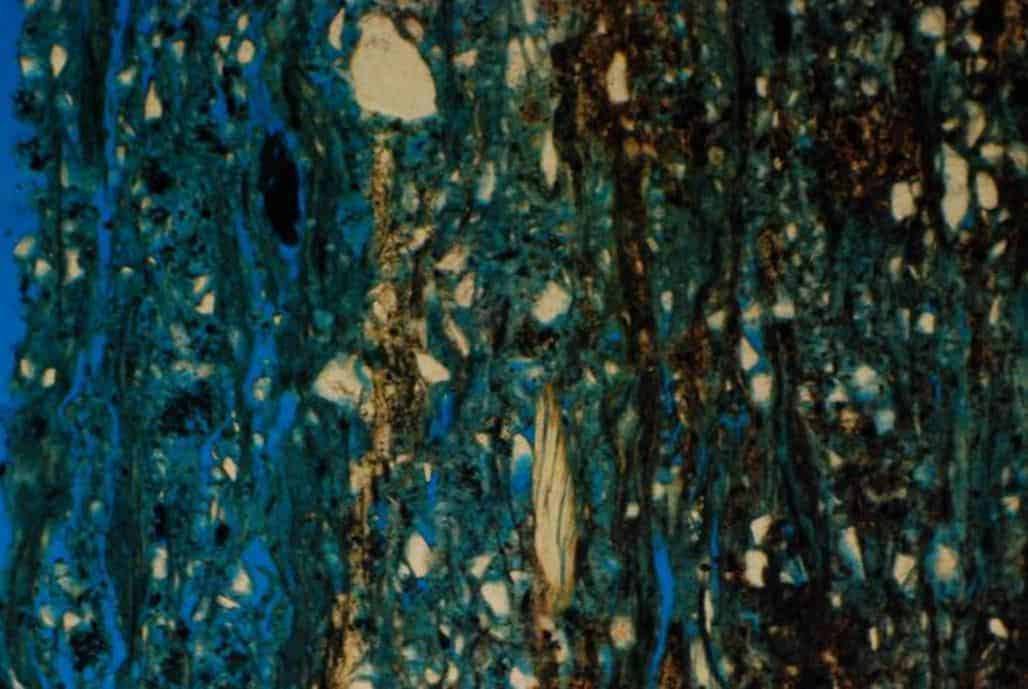

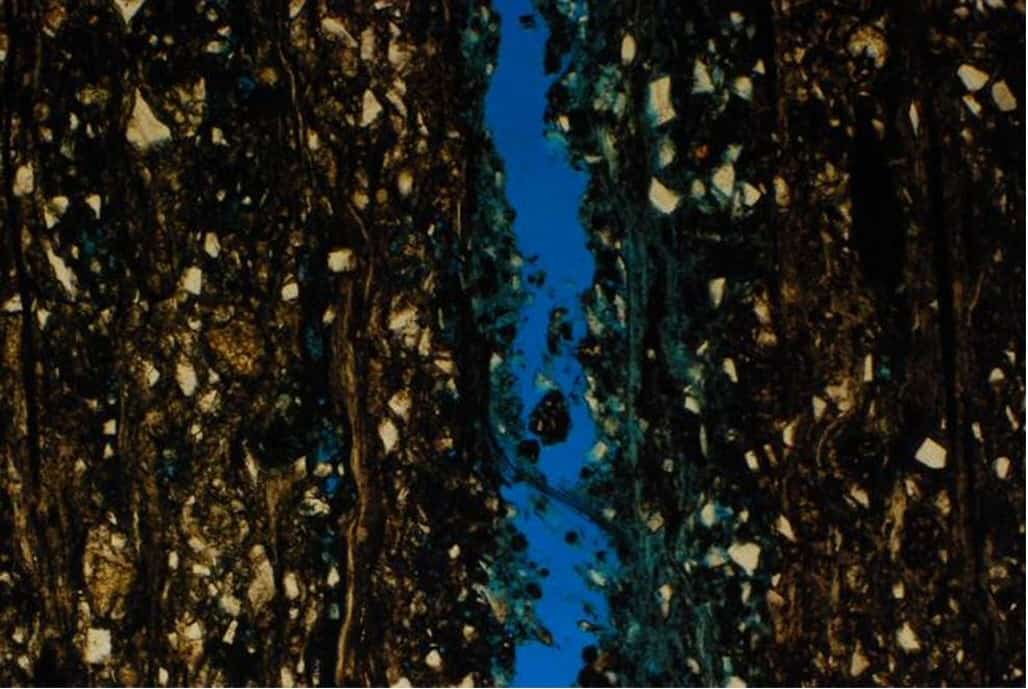

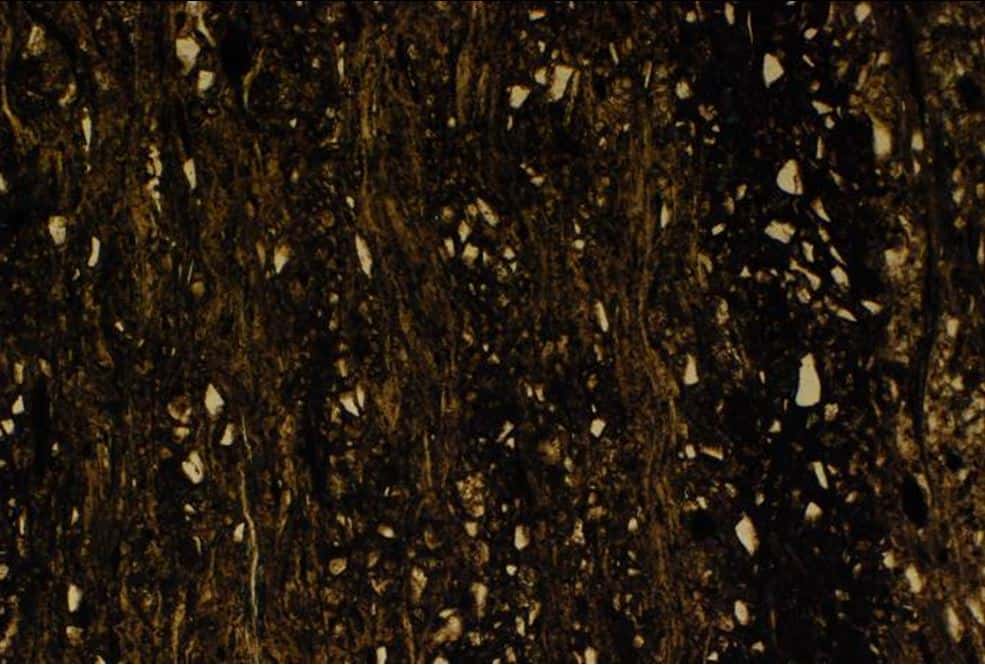

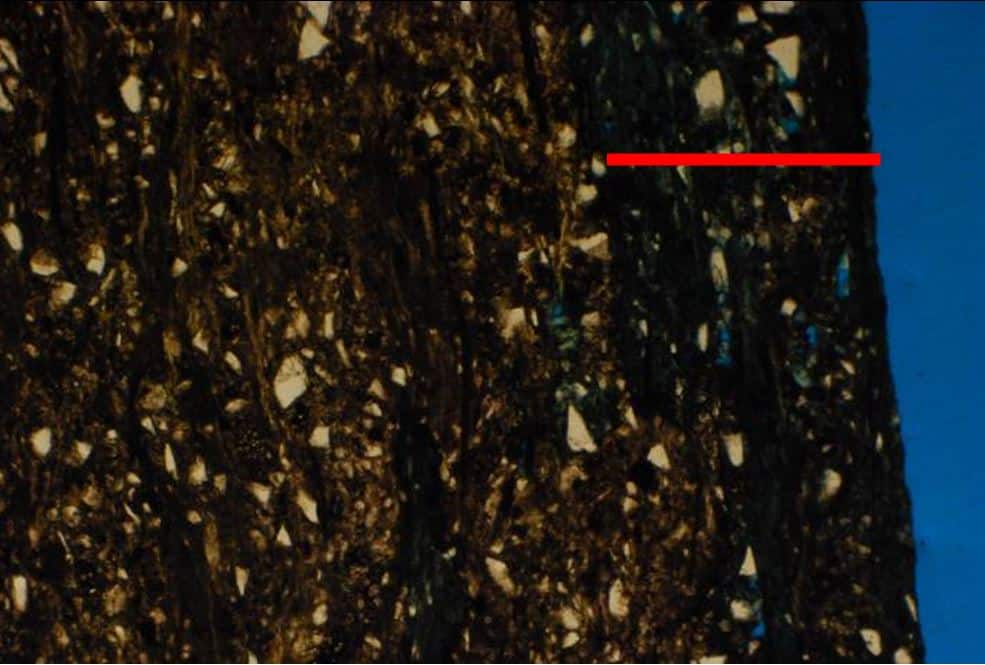

Examination by petrographic analysis showed three distinct carbonated areas and two uncarbonated areas. The extremities of the pipes are carbonated and about the mid-section of the pipe where a crack appears also show a band of carbonated layer.

Figure 3 (a, b, c, & d) show representative cross section of pipe.

DISCUSSION OF RESULTS

Carbonation of a band on the pipe closer to the inner wall may have contributed to the crack formed close to the mid-section of the wall of the pipe.

Consulting Engineers

Concrete Experts

"C3S, Inc. is a concrete consulting firm dedicated to providing full scale services to civil, A/E firms, government entities, testing laboratories, property managers and owners, and other agencies dealing with projects related to concrete.

With its immense expertise, C3S. Inc. has been successfully serving clients in U.S and worldwide markets for over 30 years. "

CONTACT INFORMATION

C3S, Inc.

7100 Regency Square Blvd.

Suite 183

Houston, TX 77036

Office Hours

Mon-Fri: 8 AM - 5 PM

Sat-Sun: Closed