Concrete Testing

C3S Concrete Testing Services

Concrete Testing

We select the appropriate concrete testing for your structure based on its suitability and its intended use. Our objective is to assess existing condition of structure and provide recommendations based on findings.

We go beyond the traditional concrete testing to determine condition of concrete and related construction materials. Experience matters.

Compressive Strength (ASTM C39) Concrete Testing

C3S performs compressive strength concrete testing utilizing the procedure set forth by ASTM C42 – Standard Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete. This concrete testing is performed to determine if the concrete meets the required compressive strength specified in the construction documents.

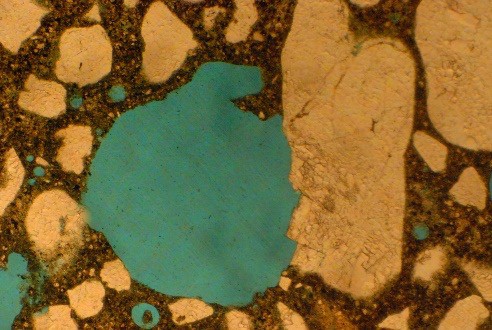

Los Angeles Abrasion Test for Aggregates

C3S performs this concrete testing utilizing the procedure set forth by ASTM C 131 – Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine.

This concrete testing method is used as an indicator of the relative quality or competence of a source of aggregate. Particularly, it is effective in identifying aggregates with inherent cracks in them and the likelihood of sections of the aggregate breaking off/chipping off and entrapping large cavities in the concrete. Perennial problems of concrete pavement using weathered river gravel is prevalent in our area of southeast Houston.

This test detects these types of aggregates.

Concrete Testing for Organic Impurities in Sand

We perform this concrete testing utilizing the procedure set forth by ASTM C 40 – Test Method for Organic Impurities in Fine Aggregates for Concrete.

This test determines the presence of deleterious organic impurities in fine aggregates that have the potential of impairing the durability of the hardened concrete. Specifically, it is used in ensuring that the effectiveness of air entraining agent used to resist freeze-thaw action in cold climates is not compromised.

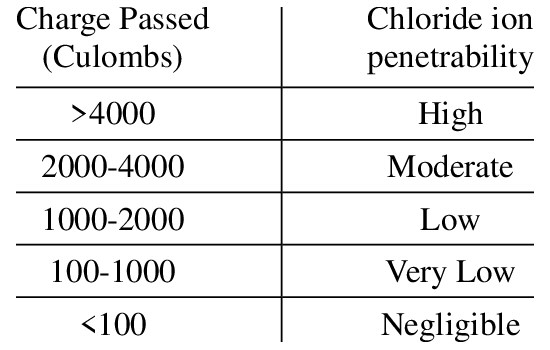

Permeability of Concrete

C3S performs Permeability of Concrete testing utilizing the procedure set forth by ASTM C 1202 – Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration.

This concrete testing method is also often resorted to in evaluation of infrastructure. Data generated from the test, by way of coulombs of electrical charge passing through a specified sample size, can be used to determine the propensity the section of the structure will readily permit fluids containing deleterious materials to gain access into the structure.

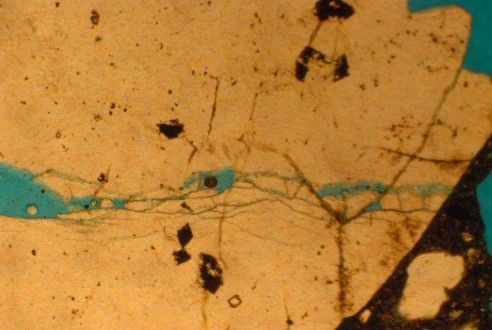

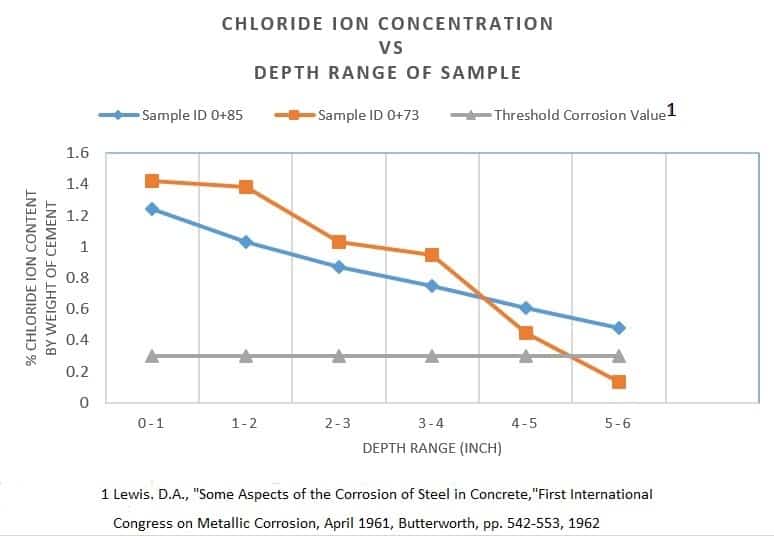

Water Soluble Chloride Content Test (ASTM C1218)

C3S performs this concrete testing utilizing the procedure set forth by ASTM C 1152 – Test Method for Acid-Soluble Chloride in Mortar and Concrete.

This concrete testing method determines the content of water-soluble chloride in new or existing cementitious mixtures. This test is used routinely in investigating potential for corrosion of embedded rebars in concrete structures. Especially in repair and rehabilitation of infrastructure where a portion of the structure is in sea/a body of water or pavements that have been subjected to salt application for ice removal.

This concrete testing method is often resorted to in assisting to determine the point within concrete where the critical chloride content to cause corrosion of rebar occur. Samples of concrete taken with a rotary impact drill at successive one-half inch depths are taken to the level of the rebar. The chloride content is separately determined for each depth and a graph developed to give the chloride ion profile in the structure.

C3S IS A GLOBAL LEADER IN CONCRETE EVALUATION

We provide quality services that our customers have come to expect.

Consulting Engineers

Concrete Experts

"C3S, Inc. is a concrete consulting firm dedicated to providing full scale services to civil, A/E firms, government entities, testing laboratories, property managers and owners, and other agencies dealing with projects related to concrete.

With its immense expertise, C3S. Inc. has been successfully serving clients in U.S and worldwide markets for over 30 years. "

CONTACT INFORMATION

C3S, Inc.

7100 Regency Square Blvd.

Suite 183

Houston, TX 77036

Office Hours

Mon-Fri: 8 AM - 5 PM

Sat-Sun: Closed