Thermogravimetric Analysis and X Ray Diffraction Analysis

C3S Thermogravimetric Analysis / X Ray Diffraction Analysis Services

Thermogravimetric Analysis

X Ray Diffraction Analysis

X-Ray Diffraction Analysis and Thermogravimetric Analysis are some of the newest tools. Thanks to our expertise and experience we eliminate all guesswork in the event failure occurs. We use innovative forensic techniques to accurately determine the cause of the problem.

We deliver results based on investigation, testing and analysis. We compile and report all our findings in succinct and comprehensive manner.

Thermogravimetric Analysis

Thermogravimetric analysis (TGA) is an analytical technique used to determine a material’s thermal stability and its fraction of volatile components by monitoring the weight change that occurs as a sample is heated at a constant rate. Thermogravimetric Analysis (TGA) measures weight changes in a material as a function of temperature (or time) under a controlled atmosphere. Its principal uses include measurement of a material’s thermal stability and composition.

Thermogravimetric Analysis instruments are routinely used in all phases of research, quality control and production operations.

Analysis Conditions:

SEIKO SSC/5200 TG/DTA 220 Thermal Analysis Station

TGA operating parameters: ceramic pans, ~ 50mg

Working gas: Argon

Temperature program: 300 to 10000C at 100C/min.

Sample Project

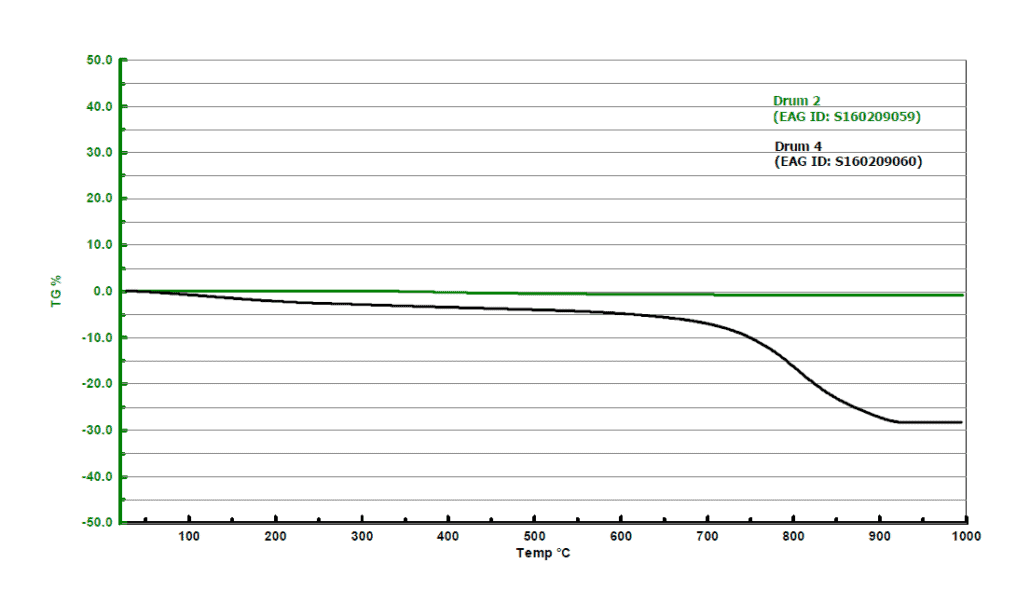

Thermogravimetric analysis was performed on the two grout samples from Drums 2 & 4. An overlay of the TGA profiles for both samples is provided as shown below . Drum 2 shows a total mass loss of 0C to ~9200 C

X Ray Diffraction (XRD) Analysis

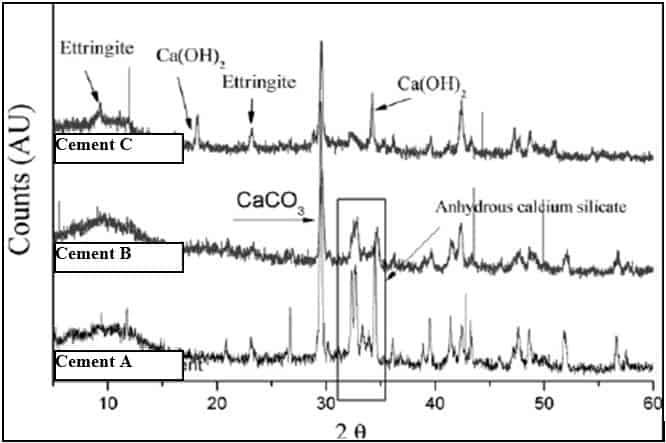

New to forensic evaluation, X Ray Diffraction (XRD) analysis is a unique method in determination of crystalline materials such calcium hydroxide ettringite and others. Thermogravimetric analysis (TGA) is an analytical technique used to determine a material’s thermal stability and its fraction of volatile components by monitoring the weight change that occurs as a sample is heated at a constant rate. X Ray Diffraction is primarily used for identifying crystalline material in investigative work in cement pastes and limestones in concrete. It is also widely used in several branches of sciences for similar applications.

A typical diffraction pattern for three types of hydrated cement paste give the results in the chart to the right:

C3S IS A GLOBAL LEADER IN CONCRETE EVALUATION

We provide quality services that our customers have come to expect.

Consulting Engineers

Concrete Experts

"C3S, Inc. is a concrete consulting firm dedicated to providing full scale services to civil, A/E firms, government entities, testing laboratories, property managers and owners, and other agencies dealing with projects related to concrete.

With its immense expertise, C3S. Inc. has been successfully serving clients in U.S and worldwide markets for over 30 years. "

CONTACT INFORMATION

C3S, Inc.

7100 Regency Square Blvd.

Suite 183

Houston, TX 77036

Office Hours

Mon-Fri: 8 AM - 5 PM

Sat-Sun: Closed