Project Planning Phase Services

C3S Project Planning Phase Services

Project Planning Phase Services

With Project Planning Phase, we aim to build the quality of concrete ingredients upfront into the client’s project to improve the life of structures and be able to reduce the maintenance costs. We accomplish this using various aspects of concrete analysis, sourcing and qualifying the planning stages.

We assist our clients in various aspects of concrete analysis, sourcing and qualifying during their projects planning stages.

Our focus is to maximize the lifespan of your project through project planning phase services.

We determine which materials are best for your structure. We place special consideration on sources, consistency of material, and overall durability. For capital projects we ensure materials are compliant to the project’s specifications and durability requirements.

Cement

C3S helps its clients to evaluate cement on capital projects for compliance to project specifications and durability requirements.

It is far less expensive to plan for quality than it is to remediate problems down the road.

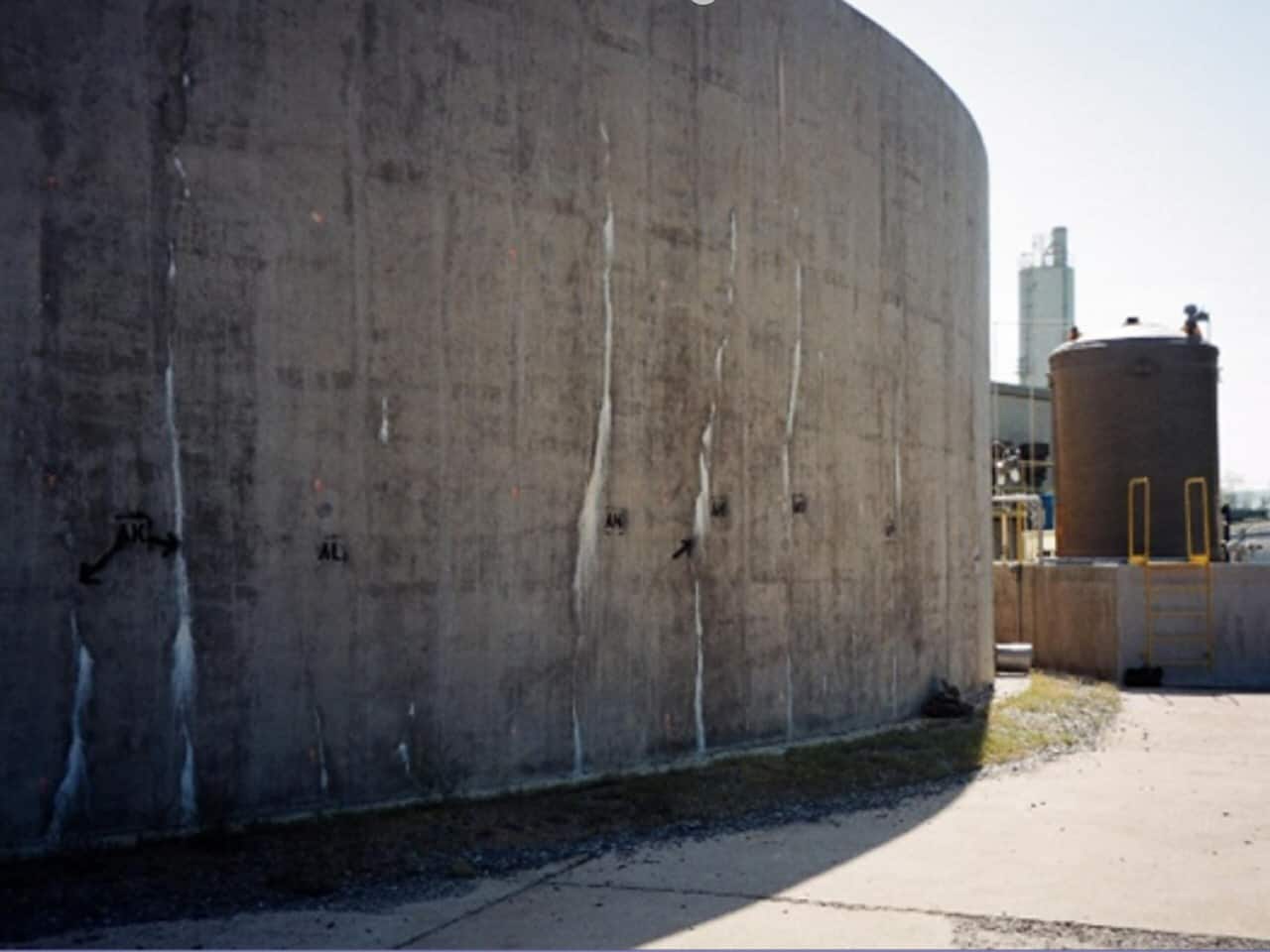

Here are two examples of problems that could have been prevented by utilizing C3S services during the project planning phase.

File photo from a project of three (3) year old water tank. Analysis revealed wrong choice of cement and high water cement ratio led to formation of expansive Ettringite in the concrete.

Aggregates

C3S helps its clients to evaluate aggregates on capital projects for compliance to project specifications and durability requirements.

The choice of aggregate for concrete is critical to a successful project. Trust C3S to help you identify and source the best aggregates for your project and to monitor that they are utilized exactly as specified.

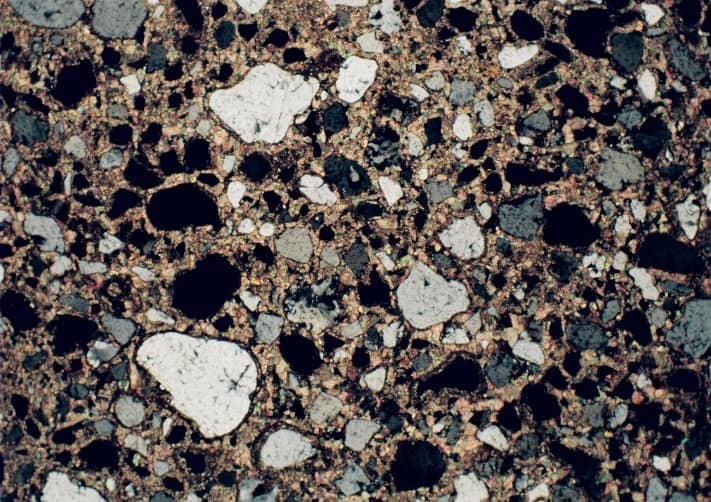

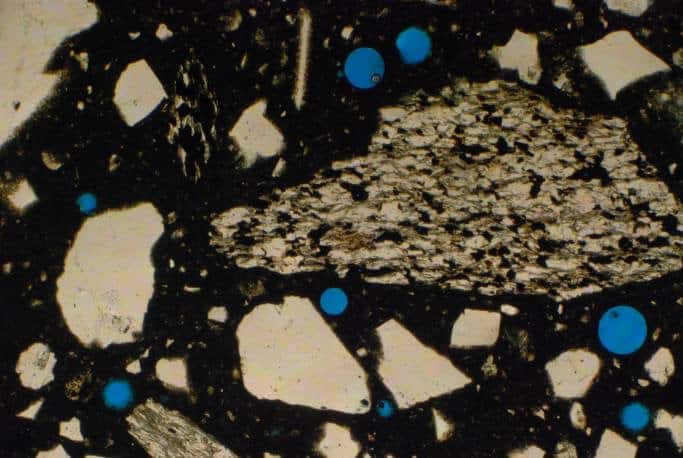

Scope: To determine whether the three rock boulders to be beneficiated into aggregates are suitable for use as construction material, specifically, that it will not pose a threat of alkali-silica reaction, ASR, in concrete.

Note – Picture above shows cracks through the aggregate in one of the samples sent to us.

Mineral Admixtures

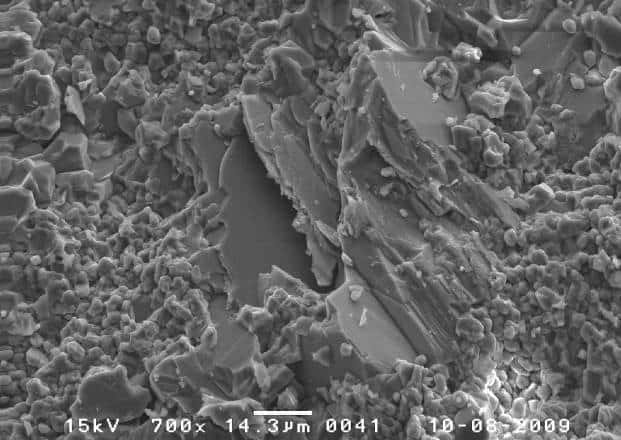

A section of a major highway between two major cities in Texas experienced surface defects about two years after completion. A three mile stretch had to be replaced. Samples evaluated in connection with the problem pointed to a high dosage of mineral admixture used in the affected section of the pavement.

Choice of mineral admixture (i) – to optimize concrete placement in varying weather conditions, and (ii) improve durability of hardened concrete. Examples of damage to structure due to contribution by mineral aggregate used.

Mineral Admixture Contribution to Pavement defect

Chemical Admixtures

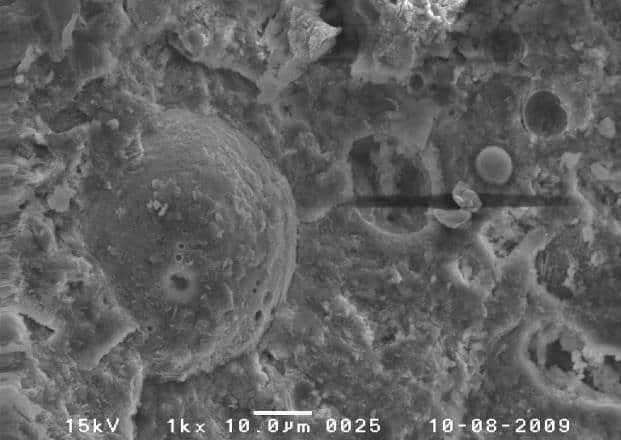

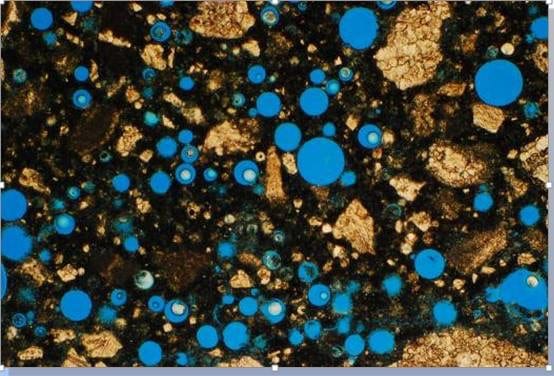

Examples of entrained air content, mostly for long term durability of concrete, in freeze-thaw regions can adversely affect compressive strength of the concrete if in excess.

If entrained air content is below the specified amount it raises long term durability concerns, and in some instances, affected sections of the structure may have to be replaced.

Inadvertent dosage of air entraining agent – a high air content – causes a loss in compressive strength in a concrete on a highway project.

(Blue, round circles are entrained air in a petrographic evaluation)

C3S IS A GLOBAL LEADER IN CONCRETE EVALUATION

We provide quality services that our customers have come to expect.

Consulting Engineers

Concrete Experts

"C3S, Inc. is a concrete consulting firm dedicated to providing full scale services to civil, A/E firms, government entities, testing laboratories, property managers and owners, and other agencies dealing with projects related to concrete.

With its immense expertise, C3S. Inc. has been successfully serving clients in U.S and worldwide markets for over 30 years. "

CONTACT INFORMATION

C3S, Inc.

7100 Regency Square Blvd.

Suite 183

Houston, TX 77036

Office Hours

Mon-Fri: 8 AM - 5 PM

Sat-Sun: Closed