The Evaluation of Blisters on Concrete Slab Project

- Date: October 2020

- Project Type: Maintenance/Forensic Phase

The Evaluation of Blisters on Concrete Slab Project

About this Project

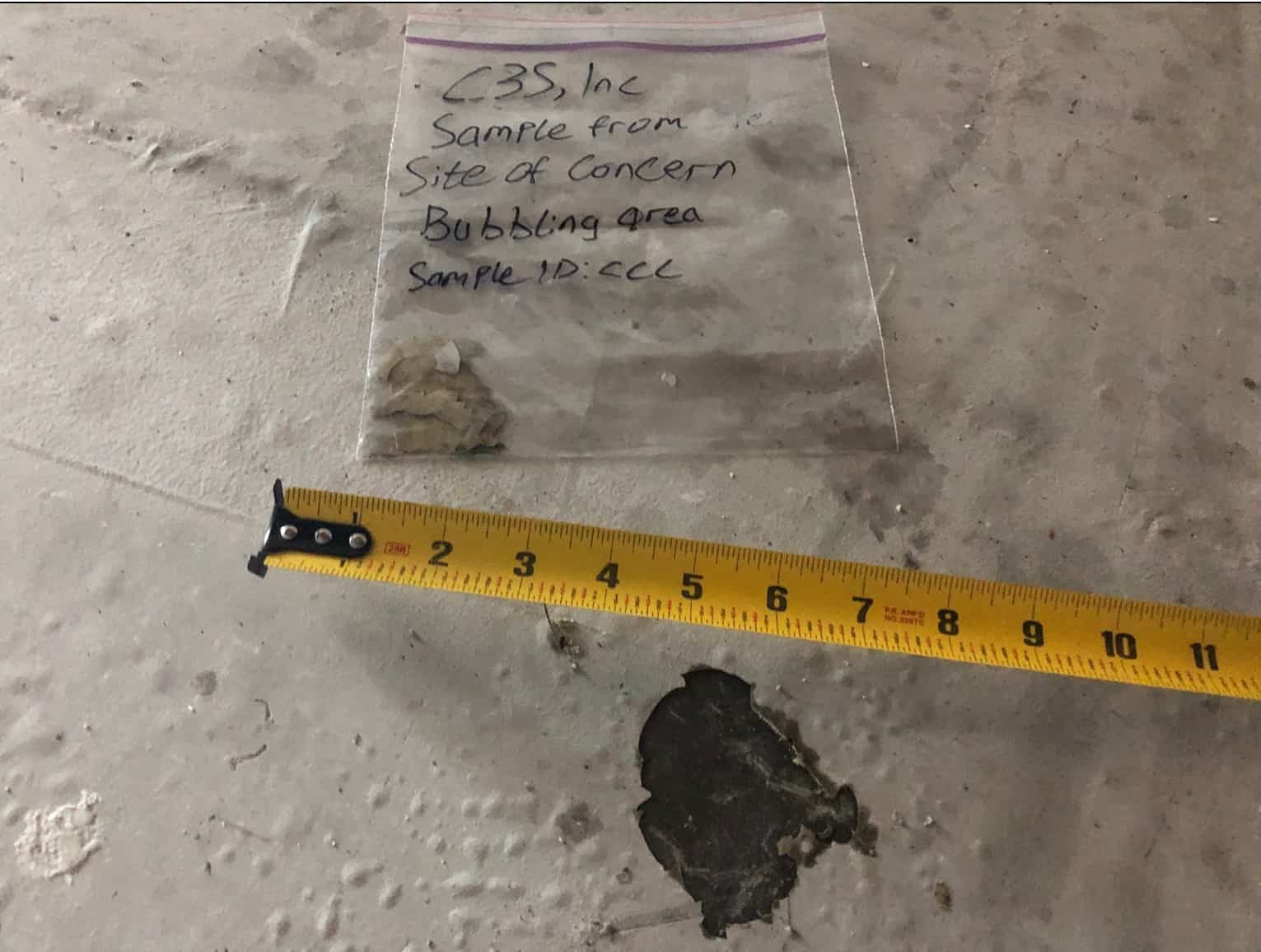

C3S performed a condition assessment of the site, obtained samples of unused/premixed seal coat, in-situ seal coat, liquid found in the blisters and four (4) concrete cores. The causes of the defects are to be evaluated using microscopic evaluation, Gas Chromatography Mass Spectrophotometry, and Fourier-Transform Infrared spectroscopy.

Note – This featured project report is an abbreviated version of the actual report prepared for the client.

Unexplainable Blistering of Slab Coating

Tests Performed:

The following tests were performed on the samples.

A. Microscopic evaluation of concrete sections.

B. Gas Chromatography Mass Spectrophotometry (GC-MS) on liquid extracted from Blisters.

C. Fourier-Transform Infrared spectroscopy (FTIR) performed on: 5 lab-proportioned mixes of the seal coat product, samples of coating from Blistered and Non-blistered areas of the slab and samples of coating from a satisfactorily performing slab at a different building.

Findings:

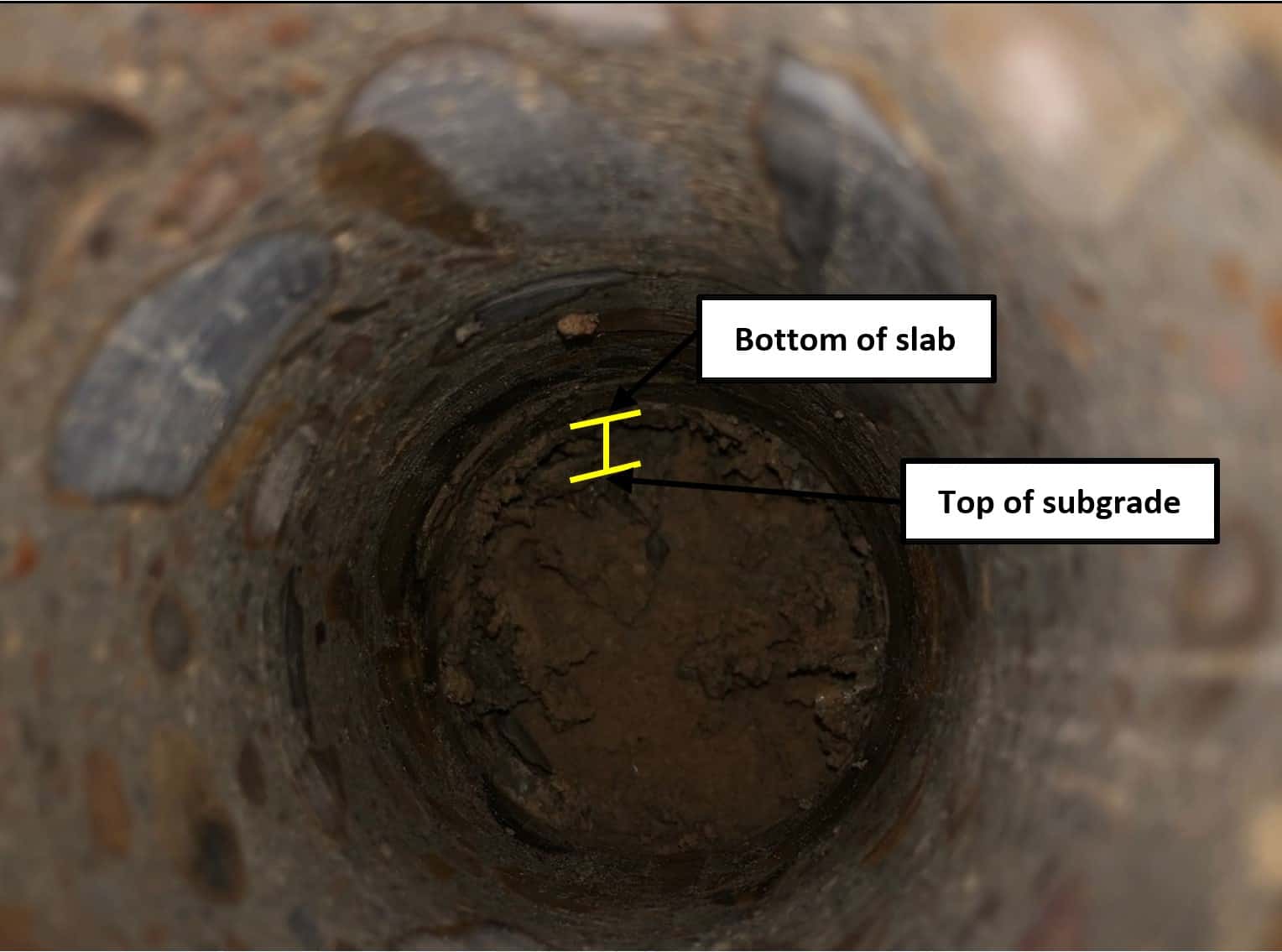

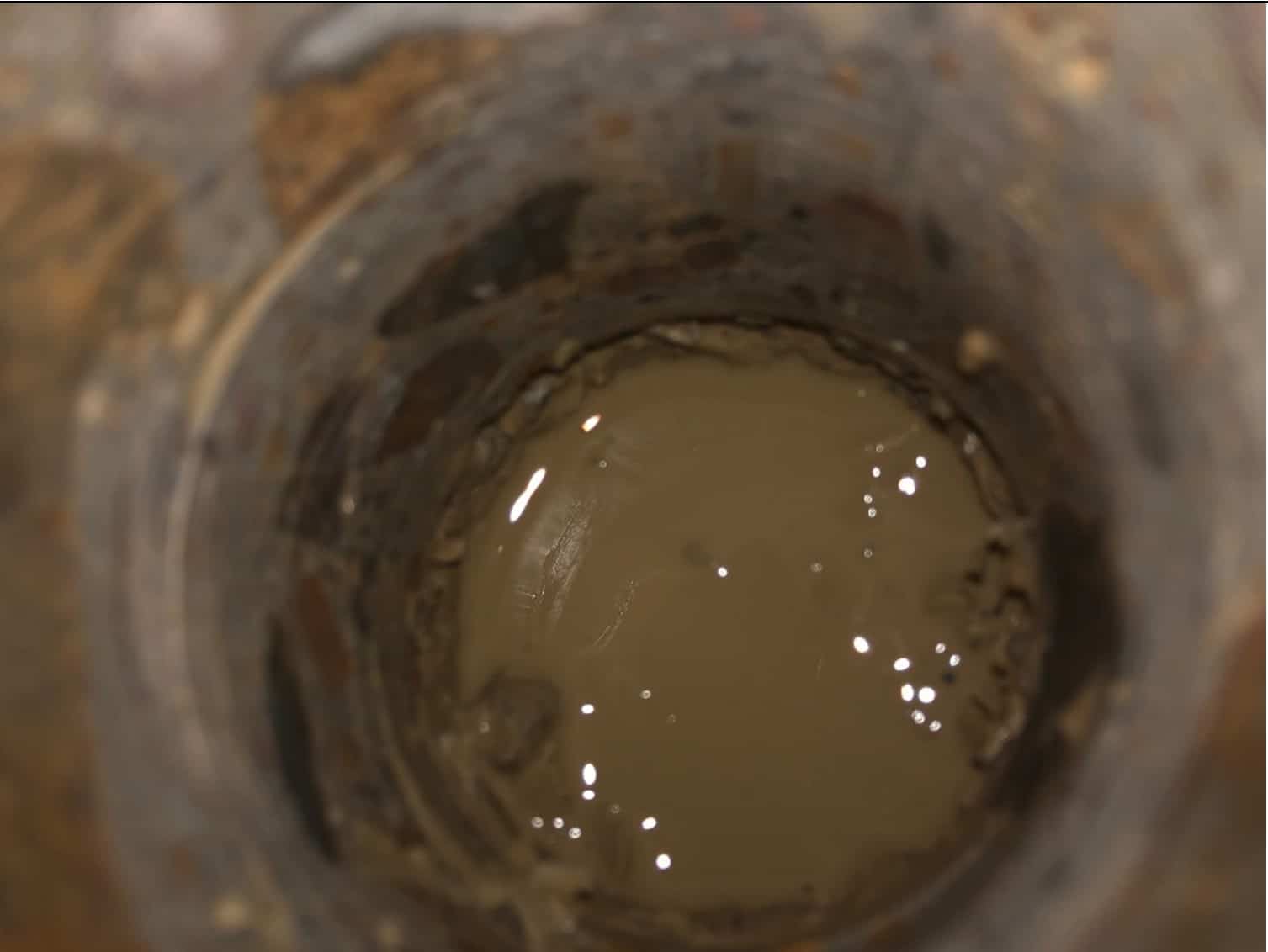

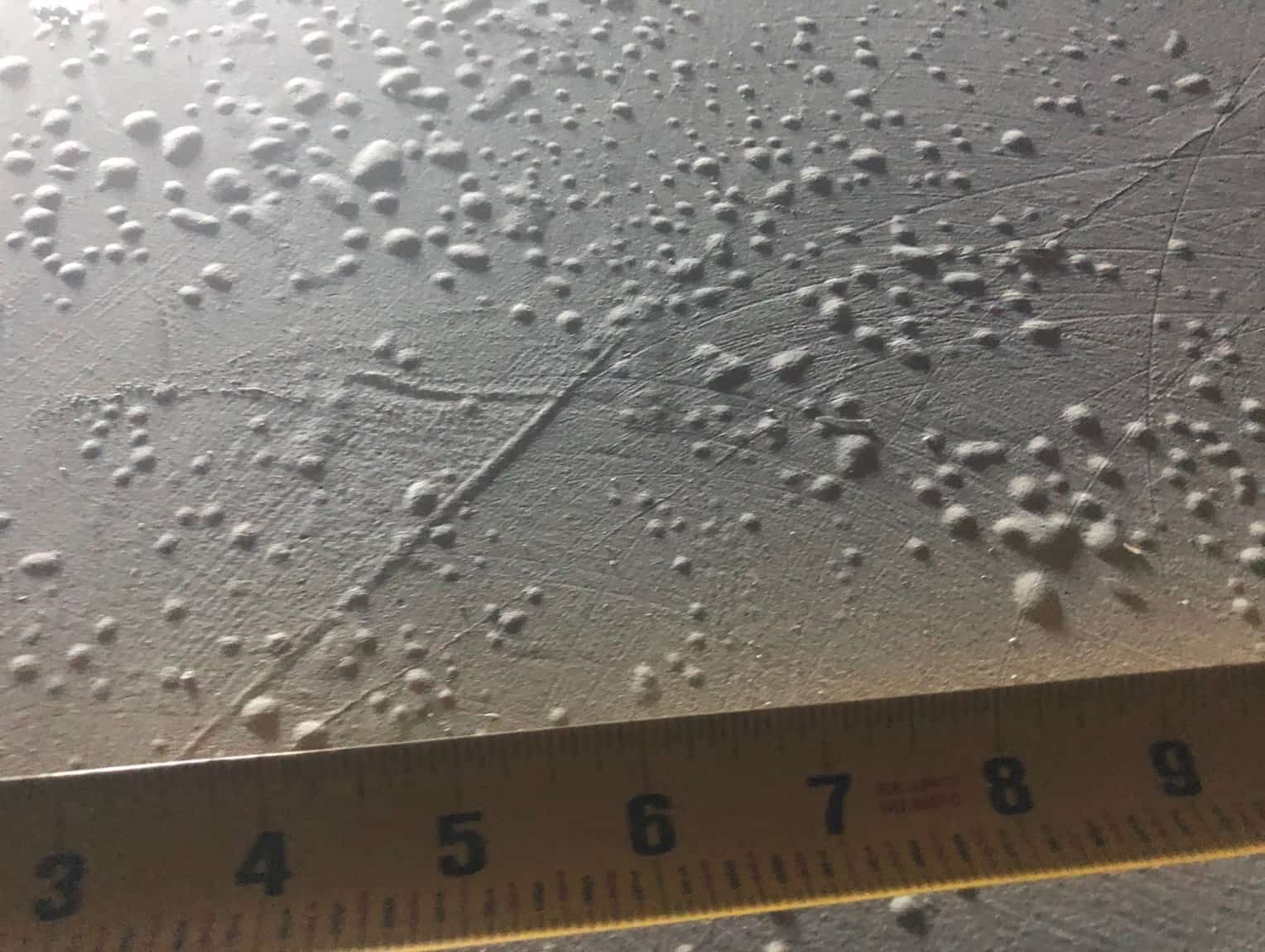

Observations during coring showed there was a ~ ¾” gap between the bottom of the slab and the top of the subgrade (see Figure E). Excessive moisture was noted in the void underneath the slab (see Figure F), which was a result of rain and poor drainage around the building foundation perimeter.

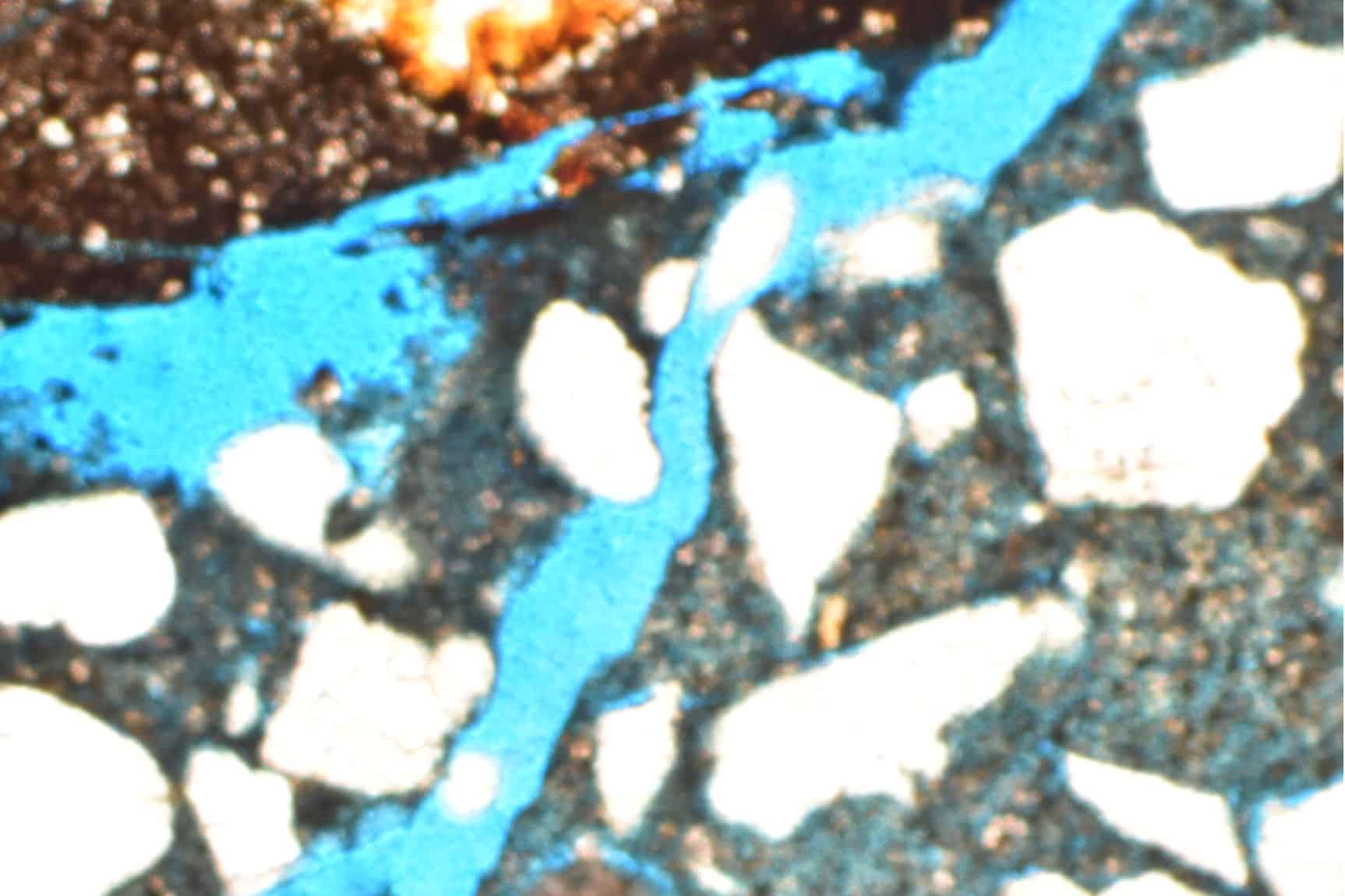

Petrographic analysis showed that the concrete slab has above normal porosity/void in the paste and aggregates used which allows for easy transmission of moisture through it (see Figure G and H).

Armed with this data, we were able to surmise that the probable series of events that cause the seal coat applied to the slab to blister is as follows: The gap underneath the slab acted as a storage space for water to be stored after rain events due to improper perimeter drainage. Water collected at the base of the slab has one easy route of escape – though the porous concrete slab. Areas in the slab where moisture being drawn to the top of the slab becomes excessive results to debonding of the seal coat, which creates blisters on the surface of slab.

Consulting Engineers

Concrete Experts

"C3S, Inc. is a concrete consulting firm dedicated to providing full scale services to civil, A/E firms, government entities, testing laboratories, property managers and owners, and other agencies dealing with projects related to concrete.

With its immense expertise, C3S. Inc. has been successfully serving clients in U.S and worldwide markets for over 30 years. "

CONTACT INFORMATION

C3S, Inc.

7100 Regency Square Blvd.

Suite 183

Houston, TX 77036

Office Hours

Mon-Fri: 8 AM - 5 PM

Sat-Sun: Closed