Concrete Non Destructive Testing

C3S Concrete Non Destructive Testing Services

Concrete Non Destructive Testing

We select the appropriate non destructive testing for your structure based on its suitability and its intended use. Our objective is to assess existing condition of structure and provide recommendations based on findings.

Concrete Non Destructive Testing condition assessment investigations can quickly uncover hidden construction defects, assess unknown features, and determine the extent of damage caused by catastrophic events. These investigations are performed on newer structures for quality assurance purposes and on older structures for repair, rehabilitation and/or renovation purposes. Non Destructive Testing methods can test on a variety of surfaces and structures. At C3S, Inc., we provide visual external condition assessment, detailed internal condition assessment, and destructive correlation testing services.

Ultrasonic Pulse Velocity (UPV) Testing

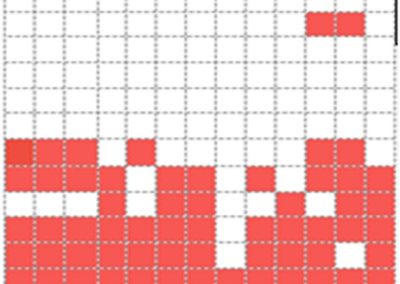

Ultrasonic Pulse Velocity (UPV) testing is non destructive testing used to determine the integrity and quality of structural concrete or stone (up to 6 feet thick) by measuring the speed and attenuation of an ultrasonic wave passing through the element being tested. Areas with lower velocities typically have lower density and strength relative to high velocity areas. Data collected along multiple test paths can be used to create tomographic images of defects.

Ultrasonic Pulse Velocity Testing on concrete is a recognized non destructive testing to assess the homogeneity and integrity of concrete. With this ultrasonic test on concrete, the following can be assessed:

- Homogeneity or uniformity of concrete in structures, post construction to check for voids, honeycombs, cracks or other defects.

- Identify areas of low-quality concrete.

- Qualitative assessment of strength of concrete, its gradation in different locations of structural members and plotting the same.

- Any discontinuity in cross section like cracks, cover concrete delamination etc.

- Depth of surface cracks. We can define the size and shape of a defect by using multiple test paths.

This is a standard ASTM test classified under ASTM C 597 – “Standard Test Method for Pulse Velocity through Concrete”

Sonic Pulse Velocity (SPV) testing is used at lower frequencies for distances greater than 6 feet, such as large columns, beams, and dams. We can test concrete, stone, or wood members up to 25 feet thick.

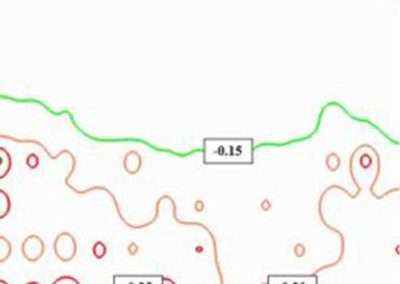

Corrosion Mapping

The Half Cell Potential (HCP) method is non destructive testing used when monitoring the corrosion activity, resistivity, and rate of reinforcing and other structural steel elements embedded in concrete. This is an electrochemical technique used to locate areas of active corrosion of steel reinforcement in a concrete slab or wall. The HCP method takes advantage of the oxidation-reduction (redox) chemical reaction from active corrosion that produces an electrical potential that can be measured externally. The corrosion activity of reinforcement bars in concrete structure is an indicative of permeability of concrete.

This is a standard ASTM test classified under ASTM C 876 – “Standard Test Method for Half-Cell Potentials of Uncoated Reinforcing Steel in Concrete”

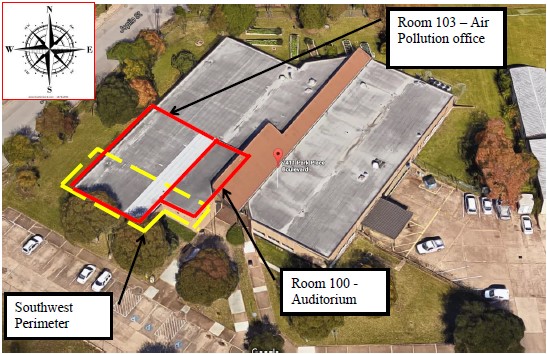

Sample projects with testing performed by C3S, Inc.

Evaluation of Three Damaged Tilt Wall Buildings

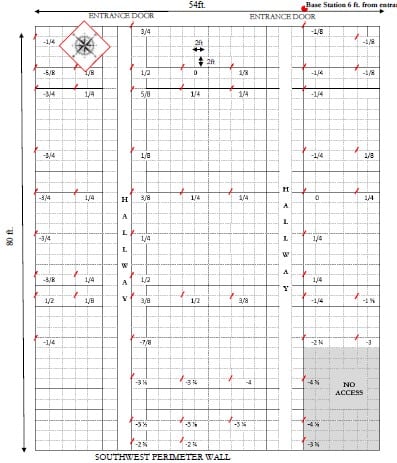

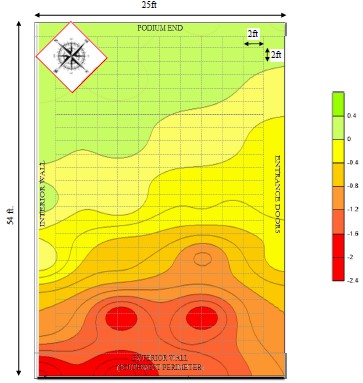

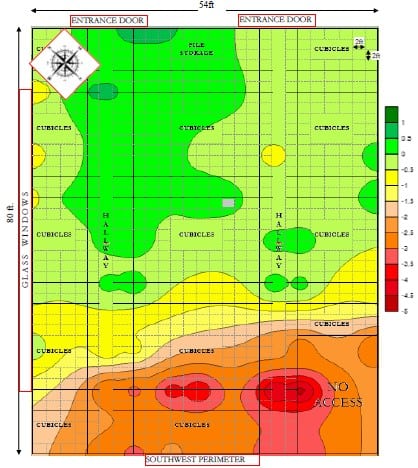

Floor Elevation Surveys

C3S, Inc. uses Foundation and Floor Elevation Surveys to study slab-on-grade or foundation movements. C3S presents data in form of 2D or 3D survey maps. These maps are useful for helping clients to identify and isolate the source of the problem and determine the appropriate repair strategies by mapping structural movements.

Floor level study to investigate slab movement for an office building

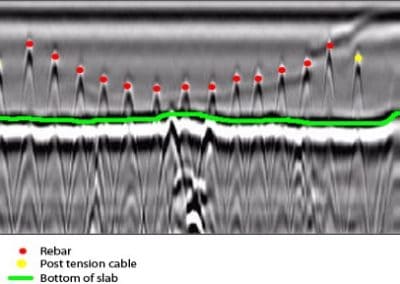

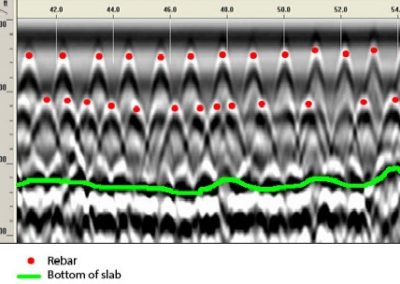

Ground Penetrating Radar (GPR) Scanning

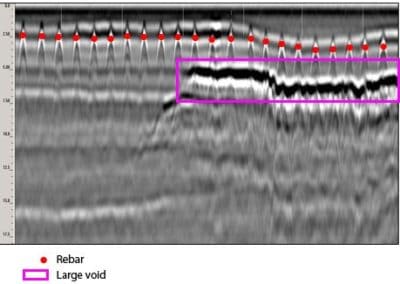

This non destructive testing procedure utilizes a portable radar unit to determine the location and depth of steel reinforcement embedded in concrete, thickness of concrete members, presence of voids within or beneath a concrete slab, and assessment of the general uniformity of the concrete.

C3S provides ground penetrating radar scanning services which is a reliable, non destructive testing means to locate targets within concrete structures prior to drilling, cutting or coring. By performing GPR on concrete, following can be assessed:

- Slab Thickness

- Concrete Cover and Rebar Location

- Voids – Location and Extents

- Pre Stressing Strands (PT Cables)

- Conduits

This is a standard ASTM test classified under ASTM D6432 – “Standard Guide for Using the Surface Ground Penetrating Radar Method for Subsurface Investigation” ( Section 1.1.2, point 11)

To complement our GPR service, we can also determine rebar size using the latest technology.

Additional Non Destructive Testing

C3S provides some other as-needed Non Destructive Testing. There are various NDT tests available for concrete structures, but they are selected based on suitability and application.

Visual Inspection

Visual inspections provides information on type, extent of damage, their possible causes and type of NDT test suitable for further investigation.

Carbonation Depth Measurement Test

This NDT is used to determine the penetration of agents of corrosion like moisture inside concrete. Its identified using Phenolphthalein indicator and is vital to assess if corrosion level has reached to the level of rebar in a structure.

Schmidt Rebound Hammer Test

C3S IS A GLOBAL LEADER IN CONCRETE EVALUATION

We provide quality services that our customers have come to expect.

Consulting Engineers

Concrete Experts

"C3S, Inc. is a concrete consulting firm dedicated to providing full scale services to civil, A/E firms, government entities, testing laboratories, property managers and owners, and other agencies dealing with projects related to concrete.

With its immense expertise, C3S. Inc. has been successfully serving clients in U.S and worldwide markets for over 30 years. "

CONTACT INFORMATION

C3S, Inc.

7100 Regency Square Blvd.

Suite 183

Houston, TX 77036

Office Hours

Mon-Fri: 8 AM - 5 PM

Sat-Sun: Closed